Pennsylvania’s Floor Coating Experts. Durable. Slip-Resistant. Installed in One Day [Get Free Quote]

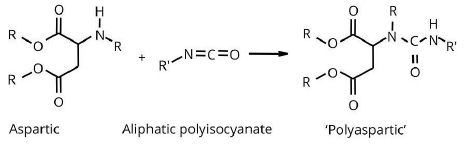

Polyaspartic coating is an advanced protective material that belongs to the same chemical family as polyurea — high-performance polymers originally developed for industrial and military use.

It’s not paint and not traditional epoxy.

It’s a two-component system made of a resin and a hardener that chemically react the moment they’re mixed, forming a dense, cross-linked network.

This reaction creates a material that bonds tightly to concrete and cures into a flexible but incredibly strong membrane — one that resists chemicals, abrasion, UV light, and impact.

In simple terms: it’s a coating engineered at the molecular level to outlast anything else applied to concrete.

What makes polyaspartic coating different is its chemical structure.

Where epoxy forms long, rigid chains (which makes it brittle), polyaspartic creates a highly cross-linked lattice — tiny chemical “bridges” that connect molecules in multiple directions.

This structure provides three key advantages:

When applied, polyaspartic material actually penetrates the microscopic pores of concrete before it hardens.

That creates both a mechanical and a chemical bond, anchoring the coating deep into the slab — not just sitting on the surface.

Epoxy coatings are hard but brittle; temperature swings and pressure cracks them.

Polyaspartic coatings, on the other hand, have controlled flexibility — they move slightly with the concrete, preventing delamination and fractures even during freeze-thaw cycles.

The molecular bonds in polyaspartic are UV-stable, meaning sunlight cannot break them down.

That’s why it doesn’t yellow or chalk like epoxy.

It’s also chemically inert once cured — resistant to gasoline, oil, salt, brake fluid, and most cleaning chemicals.

Each polyaspartic system used by Flake Pro Coatings is formulated with:

When combined and cured, these components form a continuous, seamless layer that becomes part of the concrete itself.

Polyaspartic technology was first used in heavy-duty industries — factories, hangars, and ship decks — where floors needed to survive constant abuse.

Now, homeowners benefit from that same technology in garages, patios, basements, and pool decks.

It’s ready in one day, works in any season, and stays bright and safe for decades.

That’s why more professionals now call it the “future-proof coating.”

To see how this chemistry performs in real spaces, visit

👉 Garage Floor Projects

or

👉 Our Process.