Pennsylvania’s Floor Coating Experts. Durable. Slip-Resistant. Installed in One Day [Get Free Quote]

For decades, homeowners and business owners in Pennsylvania viewed concrete flooring as a purely utilitarian necessity. It was grey, dusty, prone to cracking, and impossible to keep clean. If you wanted to upgrade it, your only real option was paint (which peeled in a month) or traditional epoxy (which took days to cure and often yellowed over time).

But the industry has shifted. A technology originally developed for protecting steel bridges from corrosion and harsh saltwater environments has made its way into residential garages, basements, and patios.

It is called polyaspartic floor coating.

At FlakePro Coatings, we believe in educating our clients. In this comprehensive guide, we will explore exactly what a polyaspartic floor covering is, the science behind its durability, why experts prefer it over epoxy, and what real homeowners in Lancaster and York are saying about their new floors.

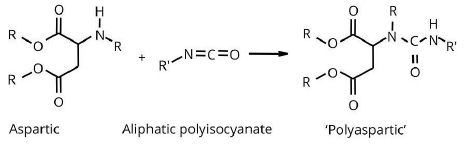

To understand why this material is superior, we have to look at the chemistry.

Technically, polyaspartic is a type of aliphatic polyurea. The technology was first developed in the 1990s by Bayer MaterialScience (now Covestro). Their goal was to create a protective coating for steel structures that could be applied in high humidity and would cure rapidly, allowing bridges and infrastructure to reopen quickly.

Unlike epoxy, which is a diverse class of prepolymers and polymers containing epoxide groups, polyaspartic is a two-component system that reacts to form a tough, rubber-like material that is both hard and flexible.

Dr. Thomas Reiner, a leading industrial chemist in the coatings industry, explains the molecular advantage:

“The magic of polyaspartic chemistry lies in its cross-linking density. Unlike epoxy, which cures into a rigid, brittle lattice, polyaspartic esters form a matrix that retains elasticity. This means when the concrete substrate expands due to thermal cycles, the coating moves with it rather than snapping. For climates with freeze-thaw cycles like Pennsylvania, this flexibility is not just a luxury; it is an engineering necessity.”

When we talk about a polyaspartic floor, we aren’t just talking about a product; we are talking about a seamless, architectural surface that bonds chemically with the concrete. You can read more about the technical definitions of these protective coatings on the Corrosionpedia definition page, which details their industrial origins.

One of the most common questions we get at FlakePro Coatings is: “Why should I pay for polyaspartic when epoxy is cheaper?”

It is a fair question. Epoxy has been the standard for years. However, traditional epoxy has significant limitations that polyaspartic solves. Let’s break down the comparison.

Epoxy: Most epoxies are not UV stable. If you open your garage door to let the sun in, or if you use epoxy on a patio, the UV rays will attack the polymer chains. Within 1-2 years, the floor will turn a sickly yellow or amber color. This is called “ambering.” Polyaspartic: It is aliphatic, meaning it is chemically stable under ultraviolet light. A clear polyaspartic topcoat will remain crystal clear for the life of the floor. Your decorative flakes will look as vibrant in year 10 as they did on day 1.

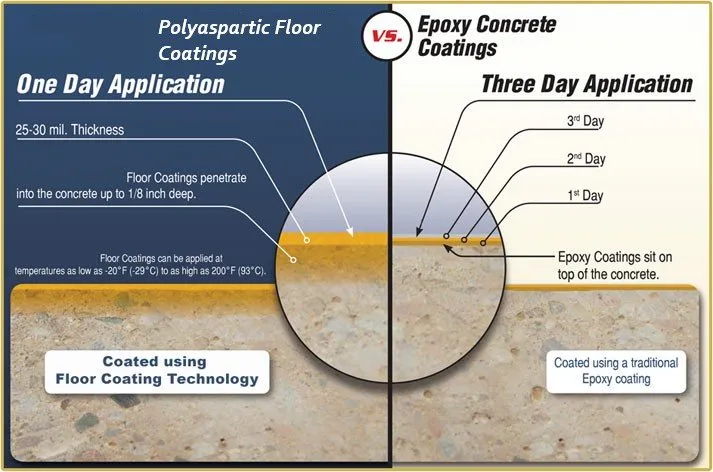

Epoxy: An epoxy system typically requires 12-24 hours to cure per coat. A proper installation can take 3 to 5 days, during which you cannot walk on the floor or park your car. Polyaspartic: This material cures rapidly. We can install a complete polyaspartic floor coating system—from grinding to topcoat—in a single day.

Tests have shown that polyaspartic coatings are roughly 4 times more durable than epoxy. They have higher abrasion resistance (meaning they don’t scratch as easily) and higher impact resistance (if you drop a wrench, it’s less likely to chip).

Polyaspartic has a unique ability to “wet out” the concrete. Because it has a low viscosity (it’s thinner than thick epoxy goo), it penetrates deep into the pores of the concrete before it cures. This creates mechanical anchors that make peeling virtually impossible if the surface is prepped correctly.

A polyaspartic floor covering is only as good as the installation. You cannot simply roll this product over dirty concrete and expect it to stick. In fact, 80% of a floor’s longevity comes from the preparation.

We invite you to learn more about our specific approach on our Garage Floor Coating Services page, but here is the detailed breakdown of our rigorous workflow:

We never acid etch. Acid etching adds moisture to the concrete, which is the enemy of any coating. Instead, we use massive planetary grinders with diamond tooling. According to the International Concrete Repair Institute (ICRI), a coating needs a specific surface profile to bond. We grind to a CSP-2 or CSP-3 (Concrete Surface Profile). This looks and feels like 100-grit sandpaper. This mechanical abrasion removes the weak top layer of concrete (laitance), old stains, and sealers. You can read more about surface preparation standards on the authoritative Concrete Network website.

Cracks and pits are the enemies of a smooth floor. We use a specialized fast-curing polyurea filler to repair cracks, spalls, and divots. Once ground smooth, these repairs become stronger than the original concrete.

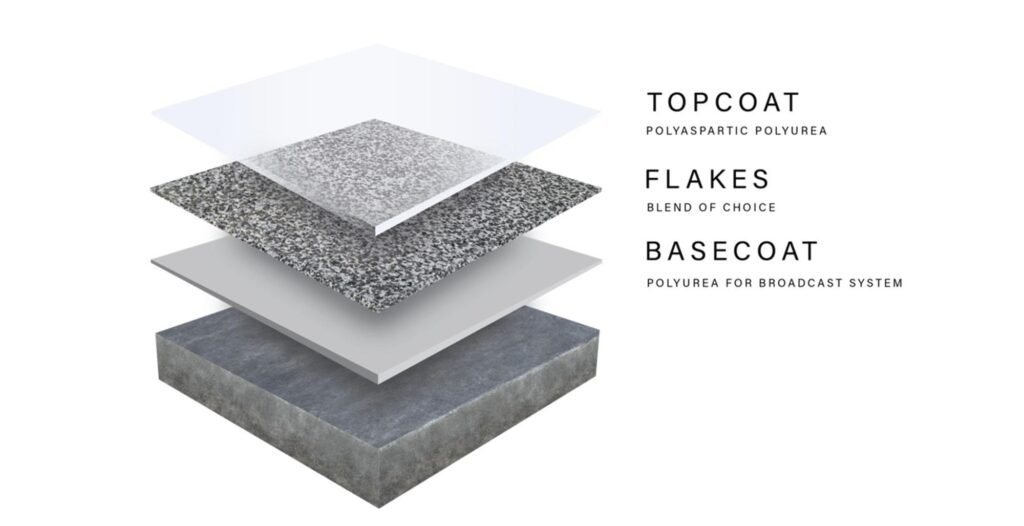

We apply a tinted polyaspartic base coat. This layer penetrates the open pores of the concrete, establishing the primary bond.

While the base coat is wet, we broadcast decorative vinyl chips (flakes) into the coating. We broadcast “to rejection,” which means we throw significantly more flakes than stick, ensuring 100% coverage. This provides three benefits:

Once cured (usually in about an hour), we scrape the floor flat to remove sharp edges from the flakes and vacuum the loose chips.

The final step is the UV-stable clear polyaspartic topcoat. This locks in the flakes and provides the chemical-resistant “shield” that you will walk on.

If we lived in Arizona or Florida, the requirements for flooring would be different. But here in Pennsylvania, we deal with a specific set of challenges: The Freeze-Thaw Cycle and Road Salts.

In winter, PA roads are covered in brine and rock salt. When you park your car in the garage, that slush melts and drips onto the concrete. Concrete is porous like a sponge. The salty water soaks in. When the temperature drops, that water freezes and expands inside the concrete pores. This internal pressure causes the concrete to flake off—a process known as spalling.

Mark Davidson, a structural engineer with over 20 years of experience in civil infrastructure, notes:

“The most destructive force for residential concrete in the Northeast isn’t weight; it’s water and salt. Once chlorides penetrate the slab, they corrode the steel reinforcement and break down the cement paste. A seamless, impermeable polyaspartic floor coating is effectively the only way to stop this process completely.”

By installing a polyaspartic floor, you are essentially waterproofing your slab from the top down. The salt sits on the coating (where it can be easily squeegeed off) rather than eating into your foundation.

While garages are the most popular application, the versatility of this material allows us to transform various areas of your home.

Basements in PA can be damp. Carpet traps mold; wood warps. A polyaspartic floor is waterproof and antimicrobial. It creates a clean, bright living space that is safe for families and pets.

Because it is UV stable, this is the perfect solution for outdoor spaces. We can add a non-slip additive to the topcoat to ensure that your pool deck is safe even when wet. See examples of our outdoor transformations on our Patio & Driveway Coating page.

Showrooms, warehouses, and commercial kitchens benefit from the rapid cure time (minimal downtime for business) and the ease of cleaning (USDA approved surfaces).

We can talk about chemistry all day, but what matters is the experience of homeowners living with these floors. Here are verified testimonials from our clients in the region.

⭐⭐⭐⭐⭐ “Saved my crumbling garage” — Brad M., Lancaster, PA

“My garage floor was a disaster. Pitted, cracked, and dusty. I thought I had to pour new concrete. The FlakePro team came in at 8 AM, and by 5 PM, the floor looked like a showroom. It’s been through two harsh winters now with road salt and snow blowers, and it still looks brand new. Best investment I’ve made for the house.”

⭐⭐⭐⭐⭐ “Better than the DIY kit” — Sarah Jenkins, York, PA

“My husband tried to do an epoxy kit from Home Depot three years ago. It peeled up where the tires sat within six months. We finally decided to call the pros. The difference in thickness and quality of this polyaspartic floor covering is night and day. Don’t waste your money on the hardware store stuff.”

⭐⭐⭐⭐⭐ “Clean and Professional” — Mike T., Lititz, PA

“I was worried about the smell because my workshop is in the basement. The team used a low-odor system and ventilated everything. It cured so fast we were moving boxes back in the next morning. Highly recommend.”

One of the biggest selling points of a polyaspartic floor coating is how easy it is to maintain. You can say goodbye to scrubbing stains.

Your floor is the foundation of your space. Whether it is the garage where you park your pride and joy, or the patio where you host summer BBQs, you deserve a surface that is beautiful, safe, and built to last.

Polyaspartic floor coating is not just a trend; it is the new standard in home improvement. It solves the problems of peeling, cracking, and yellowing that plagued the industry for years.

Don’t settle for ugly concrete or cheap paint.

If you are ready to transform your space with a professional polyaspartic floor, the team at FlakePro Coatings is here to help. We serve Lancaster, York, Harrisburg, and the surrounding Pennsylvania areas.

Ready to get started? Visit our Contact Page for a free, no-obligation estimate, or call us today at 717-419-5885. Let’s make your floors the envy of the neighborhood.